The Future of Synthetic Yarns

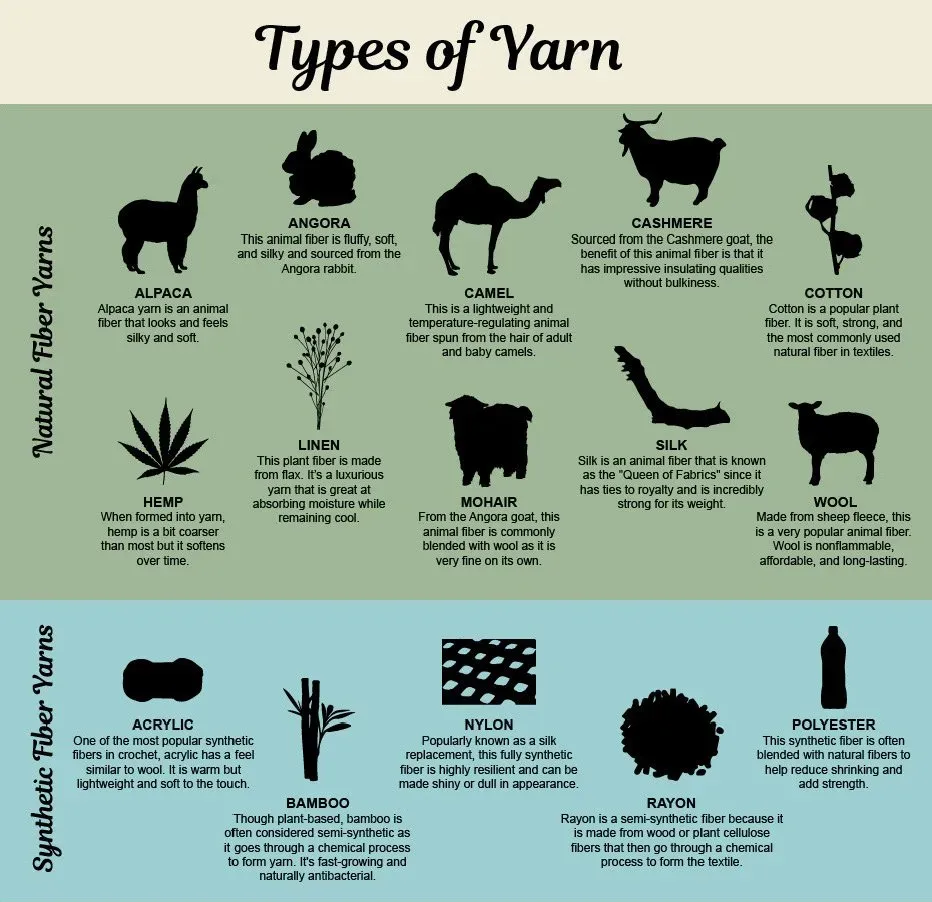

The development of synthetic fibers has revolutionized the textile industry. These fibers are made by combining chemicals into long chains of molecules called polymers. They're much stronger than natural fibers, and can be dyed and blended to create many different colors.

Why Do We Need Synthetic Fibers?

Synthetic fibers are often more durable than natural ones. This means they can withstand high temperatures and resist damage better. They also tend to last longer because they don't break down as quickly. Natural fibers like cotton and wool degrade when exposed to sunlight, air, water, and other elements.

The first synthetic fiber was invented in 1851 by Charles Goodyear. He created rubber from vulcanized animal intestines. In the early 1900's, DuPont developed nylon, which is still used today. Nylon is stronger than silk and has a higher melting temperature than wool. Today, we use polyester, acrylic, and spandex in our clothing. These materials are much lighter than cotton and wool, making them easier to wear.

The most common types of synthetic fibers include polyester, acrylic, nylon, and spandex. Polyester is the most popular type of synthetic fiber. It is strong, lightweight, and easy to dye. Acrylic is similar to polyester, but it is softer and more flexible. Nylon is very strong and resistant to heat and chemicals. Spandex is a stretchable material that is commonly found in athletic apparel.

Why Are Synthetic Fibers So Important?

Synthetic fibers are an essential part of modern life. They are used in everything from clothing to household products to medical devices. However, there are some limitations to the use of synthetic fibers. For instance, they are not as durable as natural fibers, so they tend to wear out faster than other materials. Also, they are often less biodegradable than natural fibers. This means that they will remain in landfills longer than natural fibers. There are two main reasons why people use polyester fibers. First, polyester is very durable. It does not break easily and lasts longer than cotton. Second, polyester is very easy to dye. Dyes work well on polyester because it absorbs them quickly. Cotton, on the other hand, takes much longer to absorb dyes.

What Are Some Applications For Synthetic Yarns?

The use of synthetic fibers has grown exponentially since the 1950s. Today, there are many different types of synthetic fibers available. These include polyester, nylon, acrylic, spandex, and others. Each type of fiber has its own unique properties. For example, polyester is strong and resilient, while nylon is soft and flexible. Spandex is stretchy and elastic. And acrylic is heat resistant.

What Is the Future of Synthetic Yarn?

As technology continues to advance, so will the use of synthetic yarns. We'll continue to see innovations in the future, such as 3D printing with synthetic yarns.

The future of synthetic yarns is bright. In fact, we're already seeing some amazing developments in the field. For example, scientists at the University of California, Berkeley, have developed a new type of yarn that's stronger than steel. And researchers at the University of Texas at Austin have created a new kind of yarn that could be used to create clothing that doesn't require ironing.

The future of synthetic yarns isn't limited to clothing. Scientists are working on developing other uses for synthetic yarns, such as creating artificial muscles. Researchers at the University of Illinois have been able to develop a synthetic muscle that is stronger than human muscle tissue. And scientists at the University of Michigan have created a synthetic material that can be used to create a variety of different types of fibers.

Bio Synthetic Yarn from Heiq

Yarn is made up of strands of fiber twisted together. It comes in many forms, from cotton to wool to silk. Cellulose fibers are long chains of sugar molecules that make up plant cell walls. They are found in wood, grasses, and trees. Bacterial cellulose is a form of cellulose produced by bacteria. It is stronger than regular cellulose because it contains fewer water molecules.

Beekaylon's Innovative Textile Products

Conclusion

Synthetic yarn fibre accounts for about 62% of the world market today. That is about 80 million metric tonnes and it is projected to 100 million metric tonnes by the year 2030. Most of the synthetic yarn is made from fossil fuels. But the problem with recycling is that, it requires energy as well! Which uses up the energy saved by recycling. So, the only way out is to make synthetic fibre out of renewable sources of energy, which is going to be the biggest challenge for Textile Industry going forward.

Want more information?

Beekaylon Synthetics Pvt Ltd.

15-17 Maker Chambers III, 1st Floor, Jamnalal Bajaj Road, Nariman Point, Mumbai, Maharashtra 400021, India

+91-22-43530400